We had a problem with our plotter; it marked "unrecognized cartridge" error before finishing of each printed plan; when we repositioned the cartridge the problem was solved for a while, but it seemed a problem of poor contact with the cartridge chip (it was produced when the motor axis ink supply was activated).

To repair it, you have to access the module cartridges; first of all we need to remove the cover of Control, it is a matter of finding and removing all the screws, simple task and which information is on the internet, so that I refrain from commenting;)

1. Releasing the cartridge module

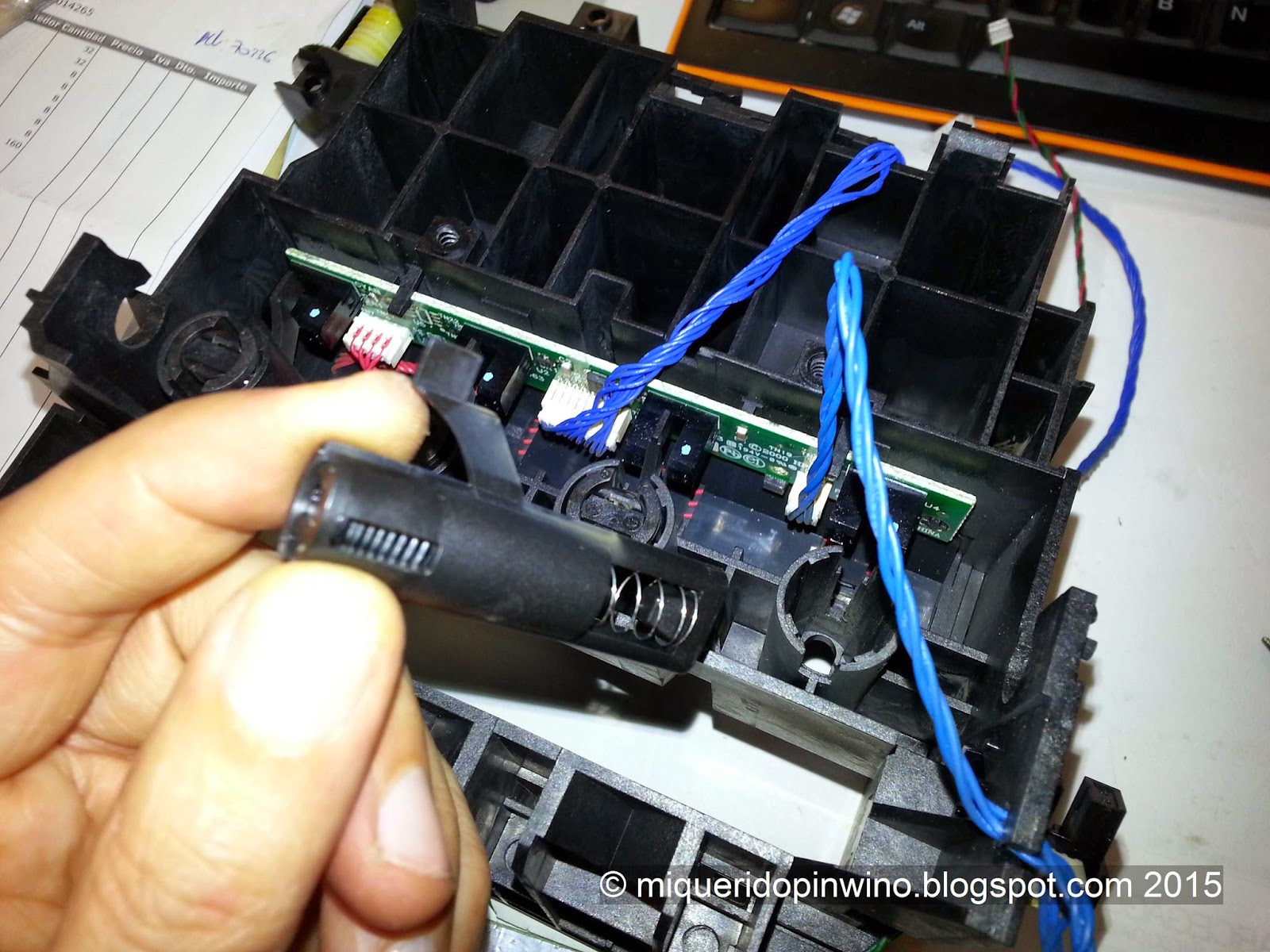

Once without the cover, release the wires that go to the cartridge magazine (blue and various colors):

We can now release the screw of the module , you see in the image below in the hollow center, which will allow us to unlock the module with a wave of right to left and then up:

If we examine the module below we can see how it is set in a metal grooves; we move it to the left and we can remove it,

not before releasing the part where needles are housed extraction. To do desanclamos the plastic tab from the metal side, and draw up:

And the piece is released:

2. Clean and check the circuit that manages the chips-counters

To repair this fault this part is not needed (you can move to the third party directly), but you should clean the optical sensors back, so we remove the axle rods that are responsible for maintaining the system pressure injection (pushing Small cartridges carrying pad at its bottom, so that only the ink cartridge or cartridges will whose pressure in the circuit is lowered by the consumption during printing).

For this we turn stops the corners to remove it:

We can remove the "piston":

And we have the easily accessible electronic circuit:

The draw for easy cleaning and repair if necessary:

We clean the dust, check that everything is correct (contact cables with plates, etc):

The module below:

3. Improving contact with the chip terminals cartridges

The terminals with chips , over time, lose some pressure force , so it can give just connection failures when the "pistons" push the cartridge.

The solution is to lift gently with a screwdriver all copper terminals:

If the problem continues, we can also give more pressure on the metal plates that hold the cartridge in place (by pressure can move), and we can draw releasing all screws from the bottom in the picture below:

No comments :

Post a Comment